The 5-axis CNC milling process is the new hotness in machining. It*s a challenge that not many can afford, but for those with the means, taking on 5-axis cnc milling can be appealing. Let*s look at some of the advantages and disadvantages of 5-axis machining over conventional 3-axis machining processes, as well as factors to consider before purchasing a machine

The advantages

? More detailed cuts can be made since the toolpath is more complex

? Higher accuracy and repeatability are possible because the number of axes is much higher than on a traditional 3-axis machine

? Cutting speeds are faster due to the multiple axes involved

? The ability to use three different materials (e.g., aluminum, copper and steel) on one part greatly reduces cost if you have multiple materials required by your project

? This type of machine can be used for manufacturing large parts with complex shapes such as gears or engine blocks, which is not so feasible with a typical CNC router system because it would require too much time and effort to program the motion parameters

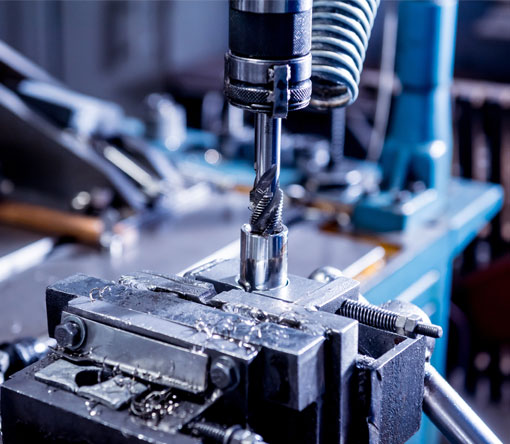

5-axis cnc machining centers for drilling