The first step to getting started with CNC drilling is to get yourself a CNC machine. These machines are available from a number of manufacturers, and you can find them in different sizes and configurations. The most common are the small desktop models that sit on your desk, but there are bigger ones that can handle larger projects

Once you've got a machine, it's time to learn how to use it! There are two basic types of CNC machines: linear and rotary. The differences between the two are what kind of machining process they use and their operating speed. A linear machine uses pulses of power instead of direct contact between the tool and workpiece; this means they're good for cutting straight lines or making patterns in wood or plastic. Rotary machines use direct contact between tool and workpiece; they're better suited for cutting corners, removing material, or doing complex operations like engraving or milling metal

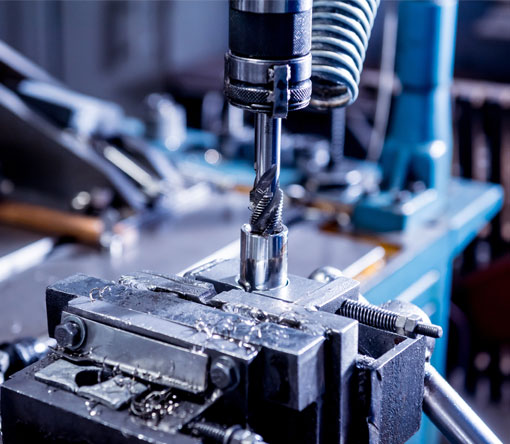

There's nothing like the satisfaction of a job well done. Whether it's cutting holes in your scrap metal for a new bench, or drilling holes in your saw blade for sharpening, mechanical and thin-kerf tools can make it easier on you and your shop. In this guide, we'll be looking at some of the basics

cnc drilling procedure