If you are in search of a CNC Program or have run across the term ※CNC§, this is the blog post for you. ?In this blog article I will discuss the CNC programming concept and how it should be done by an experienced drilling operator

The first thing to understand is that CNC is not just a programmable machine tool. It can be used to program various types of machines including milling machines, lathes and even drill presses. The most common type of CNC in use today is a 3 axis machine with two axes being fixed and one rotating with two axes moving along two separate paths. This type of machine was designed to perform repetitive tasks with minimal user interaction so that its accuracy could be increased while simultaneously reducing the amount of time required for each operation

The first step in programming a CNC machine is to define a model which contains all information about your part such as dimensions, angles, holes locations etc# This model will then be used by the computer during manufacturing so that it knows exactly where each piece needs to go on your machine during production. Once this has been done you can then create any number of programs which will control everything from setup through to cutting and more!

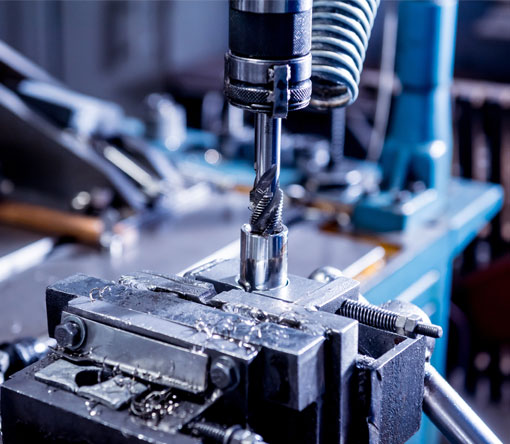

cnc vmc drilling program