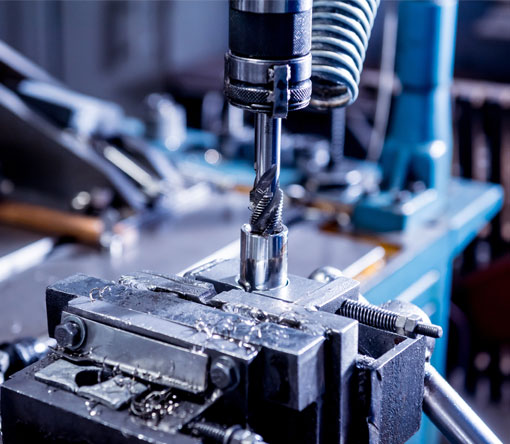

To get the perfect perpendicular G85 slot, you have to first measure the width of your attachment and make sure it's wider than the drill bit. Then, you need to take a piece of wood and clamp it in place at the desired depth. Now, take your center punch and mark off where the top of your slot will be. Then, use a drill press or hand drill to make a hole for your attachment. Finally, remove that piece of wood and insert your attachment into the new slot

If you want to build a machine that can drill a perfect perpendicular G85 slot, check out this article!

cnc drill g85 slot