In this article we'll look at the steps that you need to follow in order to drill the best holes in your CNC tubes

The first step is to determine the diameter of your tube and the size of your drill bit. You can do this by measuring the length of the tube and multiplying this by two, or you can use a caliper or micrometer

Once you have determined the diameter of your tube, you'll need to select an appropriate drill bit for your application. For example, if you are drilling through aluminum or steel, then a standard 1/8" drill bit will work just fine. However if you are drilling through wood or plastic, then a 3/32" drill bit might be required so that there is enough clearance between the tips of your cutter and the material being drilled through

If all else fails, try using a carbide tipped spiral shank bit with an oscillating spindle speed of ~15000 rpm (high speed) and feed rate of ~6000 ipm (high feed). This combination will ensure maximum accuracy while also cutting through materials like aluminum and steel very quickly!

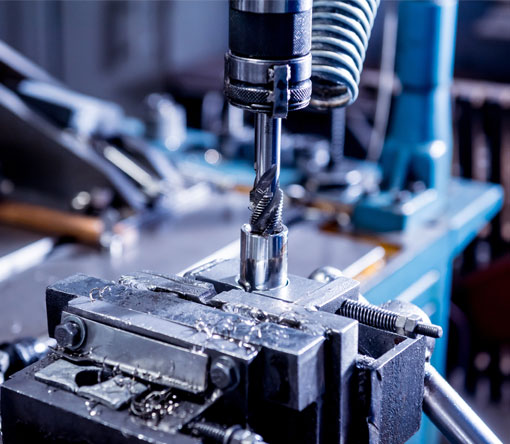

cnc tube sheet drilling