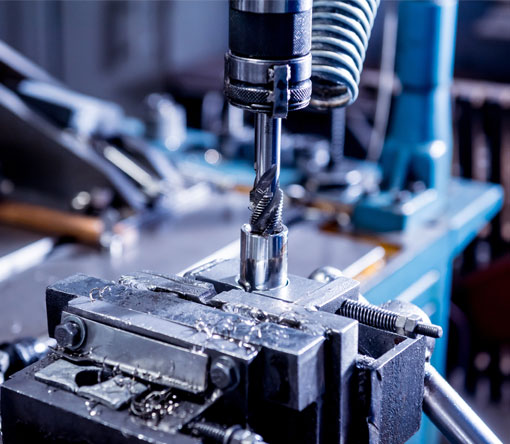

Mill drill cnc conversion kits are designed to speed up the drilling and milling tasks in different industries. In this blog post, we will look at the main types of mill drill cnc conversion kits available and tell you why those kits can improve your workflow

Mill Drill CNC Conversion Kits are used to convert a manual drilling machine into a CNC machine with the help of a computer numerical control (CNC) controller, which allows for more precise positioning and movement of the spindle, cutting tool and workpiece. These kits allow for fast and easy drilling without the need for an operator or additional staff resources

There are three main types of Mill Drill CNC Conversion Kit

Manual Drilling Machine - This type of kit is used when there is no need to automate a manual drilling machine. The operator manually loads materials into a hopper on the front of the machine and then runs it through an automated process that moves along guide rails or tracks in order to cut out different shapes or patterns from material such as wood or plastic using a variety of cutting tools including saw blades, punches, knives etc.

Batch Processing - This type of kit is designed to process large quantities at once without having to carry out each operation manually as would be required

mill drill cnc conversion kits