The best cnc drill holders on the market will be reviewed and scored from a variety of angles, including

Pric

Durabilit

Ease of us

Quality of constructio

Design features

cnc drill holdersThe best cnc drill holders on the market will be reviewed and scored from a variety of angles, including

Pric

Durabilit

Ease of us

Quality of constructio

Design features

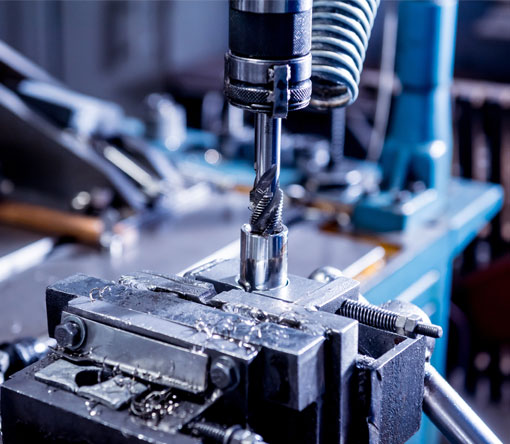

cnc drill holdersCNC drilling is a machining process in which a computer numerical control (CNC) machine is used to drill holes into a material. This process is commonly used in creating precise and uniform holes in a variety of materials, including metals, plastics.

The CNC drilling process typically use a rotating spindle and a drill bit. The spindle is driven by a motor and controlled by the CNC machine, position the locations of holes and drill it.

CNC Drilling machine instruct the spindle movement and specifies the size and location of the holes to be drilled.

During the CNC drilling process, the material is held securely in place on the machine table, and the drill bit is carefully guided by the CNC machine to create the desired holes. The speed, depth, and angle of the drill bit can be precisely controlled by the CNC machine, allowing for high levels of accuracy and repeatability.

CNC drilling can be used to create a wide range of hole sizes and shapes, including round holes, square holes, and other complex geometries. This versatility makes CNC drilling a valuable tool in many manufacturing applications, including the production of tooling parts, assembly parts, and fabrication parts.

Asianstar offers CNC drilling services to our clients on turning parts or milling parts, programming the cutters to drill the holes, deburr the holes and prepare for thread turning, etc. Drilling process are usually used to supporting sheet metal fabrication.

Our CNC drilling service is ideal for industries such as aerospace, automotive, medical, and electronics, where precision and quality are of utmost importance. We can handle large volumes of orders and can work on a variety of materials, such as metals, plastics.

We offer our CNC drilling services at competitive prices and can provide quick lead time to meet our clients' deadlines. Our team can provide technical support and advice on the best drilling techniques and tools for your specific project.

| Unit (mm) | Min | Max |

|---|---|---|

| Width | 5 | 600 |

| Length | 5 | 800 |

| Height | 5 | 300 |

| Sides | 1 | 6 |

| Hole Size | 0.3 | above |

| Unit (mm) | Drilling Hole Tolerance according to sizes | |||

| Height Tolerance | Height Size | 5 to 20 | 20 to 30 | 30 above |

| Tolerance | ±0.005 | ±0.01 | ±0.01 | |

| Length Tolerance | Length Size | 5 to 30 | 30 to 100 | 100 above |

| Tolerance | ±0.01 | ±0.015 | ±0.02 | |

| Tolerance Class followed | Tolerance (mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.015 | ±0.02 | ±0.03 | ±0.05 | ±0.10 | ±0.15 | ±0.02 | ±0.025 | ±0.03 | ±0.035 | ±0.02 | ±0.03 | ±0.04 | ±0.05 |

| Type of Drilling Machine | Height Size (mm) | Length Size (mm) | Productivity (PCS/Month) | ||||

| Turning-Milling Machine | Drilling Lathe | CNC Machine with Drilling Cutter | Min 5 | Max 300 | Min 5 | Max 800 | 200’000/Item |

Yes, we support ODM/OEM, we provide custom-made service for clients or even support clients on designing or improving