If you*re into cutting, turning or milling, you*ve probably wondered about CNC manufacturing process and its machines. You may have even thought about buying one for your own workshop. But before you do that, let us take you through a brief tour of the technology

What is CNC

CNC stands for Computer Numerical Control and refers to the use of computerized control systems to direct the motion of cutting tools. The term is derived from the French word &moteur* which means engine in English

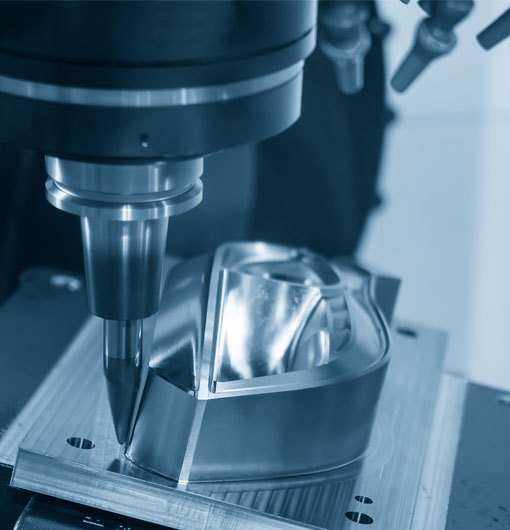

CNC manufacturing process involves programming and controlling computer numerically controlled machine tools to perform a specific set of operations on a workpiece. These tools are programmed using CAM software and can be used for machining precision parts or entire assemblies at high speeds without human intervention

The benefits of CNC include

Higher speed and productivity: CNC machines can operate at much higher speeds than traditional manual machines as they don*t require human labor

High accuracy: CNC machines can produce parts with tolerances as low as 0.1mm

Lower cost: This technology is highly cost-effective in comparison to traditional manual machining methods due to

china 4060 cnc milling bits