In this blog post, I'll show you how a cnc turning milling machine works from getting the material in, to placing the parts and finishing off

The first thing that happens is that we need to feed the material into the machine. The material has to be fed into the machine in such a way that it can be turned at high speed without breaking or bending. This can be done by using a conveyor belt or some other method of feeding material into the machine. Since this is a fairly complicated process, I'm going to skip over it for now and talk about what happens when we get our materials into the machine

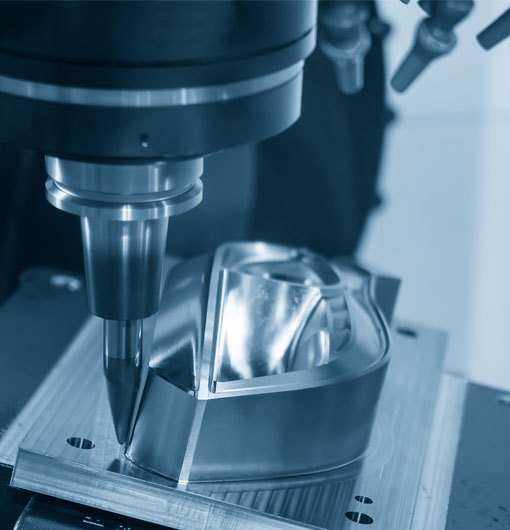

Once our material has been fed into the machine, we will have to start milling it out. This involves applying pressure onto each individual piece of material which causes them to bend and create an impression of where they are going to go on our part. The next step is moving these impressions into place on our part so we can then finish off our part with some sort of finishing process like polishing or buffing.

cnc turning milling precision parts