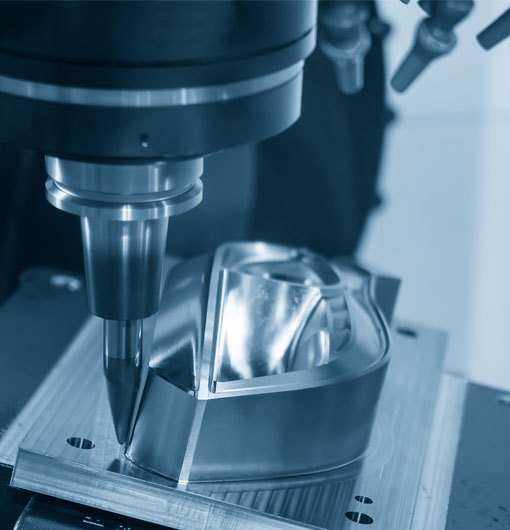

Aluminum is a great material for CNC router parts and is also an excellent choice for milling. It's lightweight, nearly indestructible, and easy to machine

Aluminum is one of the most common materials used for building professional-grade CNC routers because it has a relatively low coefficient of thermal expansion (CTE), meaning that it can be easily machined without warping or cracking. This property makes aluminum a good choice for parts that are subject to constant changes in temperature like the bearing races on your spindle

Another reason why aluminum is such an attractive material for milling with your CNC router is that it can be easily sharpened using hand tools. If you have access to a metal grinder, you can use it to remove any rough edges or burrs from your part before finishing it with a file or sandpaper. You can even use your grinder to clean up any glue residue left over from assembly if you're using an injection-molded part or part made from other materials such as plastic or wood.

cnc router parts milling aluminum