My name is Micah Thompson, and this blog is the first entry on a new series I will be writing called ※Milling a CNC Aluminum Part§. A cnc machine can have a wide variety of applications when used in conjunction with an aluminum part. In this blog post, we will be taking a look into what exactly it takes to mill a piece of aluminum with a lathe before moving over to discuss my own thoughts on the matter and how I took it upon myself to become more efficient by practicing my skills with hand tools on parts intended for milling workstations

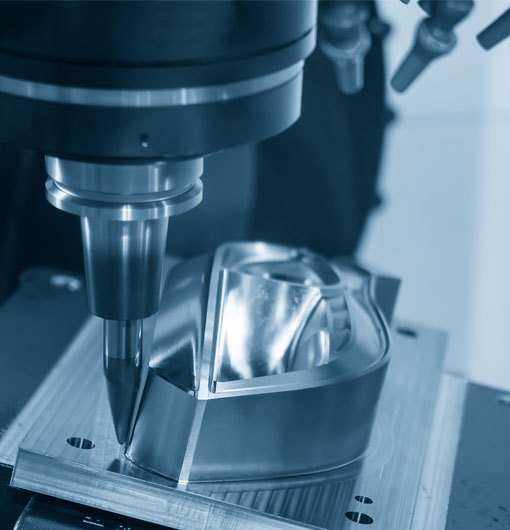

The first thing you need to do is mill out your part using an old lathe or milling machine. It is important not only to find out how much material you need in order to make your part but also how thick it should be so that you don*t end up wasting any more material than necessary. Once you have determined how much material you need along with its thickness, go ahead and start drilling holes into the shape of the part that will later be milled out. If desired, drill holes at varying depths so that they can later be filled in when welding the parts together later on down the line (see image below).

service milling cnc aluminum machining parts