The richest people in China, according to Forbes

1. Wang Jianlin - 3.2B

2. Ma Huateng - 2.7B

3. Jack Ma - 1.5B

4. Pony Ma Huateng - 1B

5. Wang Wei - 992M $

china cnc milled components factoryThe richest people in China, according to Forbes

1. Wang Jianlin - 3.2B

2. Ma Huateng - 2.7B

3. Jack Ma - 1.5B

4. Pony Ma Huateng - 1B

5. Wang Wei - 992M $

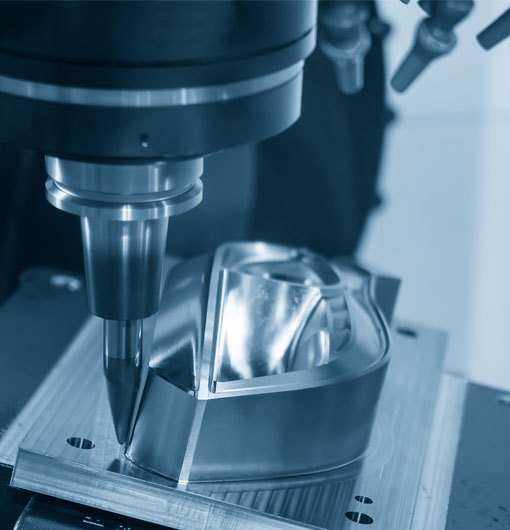

china cnc milled components factoryCNC turning is a process that CNC milling is a manufacturing process that involves the use of computer numerical control (CNC) technology uses precise instructions to control the movement of a milling machine.

In this process, a cutter removes material from a work-piece to create a desired shape or finish.

CNC milling is commonly used in the manufacturing of parts for a wide range of industries, including automotive, aerospace, and medical device manufacturing.

The CNC Milling machine is programmed with a specific design software. This program includes instructions on the size and shape of the final product, as well as the cutting paths and tooling to be used.

As staring, the work-piece material is securely clamped onto the machine’s work-table. The cutting tool is then precisely positioned and moved according to the program instructions, cutting and shaping the material as needed.

The CNC machine is able to make precise, accurate cuts and shapes with high repeatability, making it ideal for producing complex parts and designs. The process can be repeated multiple times to produce multiple identical parts.

CNC milling offers a high level of precision and efficiency in the production of components for many industries

Asianstar offers high-quality CNC milling service for a variety of industries including aerospace, automotive, medical, and defense. Our high level CNC milling machines are equipped with advanced technology and tools that allow our works reach high accuracy.

Our professional team engineers work closely with our clients to understand their specific requirements and provide custom solutions that meet their unique needs. We have the capability to handle complex geometries and shapes, and our CNC milling services can be customized to meet your specific project requirements.

We take pride in our commitment to quality and customer satisfaction, and our team is dedicated to providing timely and efficient service.

| Unit (mm) | Min | Max |

|---|---|---|

| Width | 5 | 600 |

| Length | 5 | 800 |

| Height | 5 | 300 |

| Sides | 1 | 6 |

| Unit (mm) | Tolerance according to sizes | |||

| Height Tolerance | Diameter Size | 5 to 20 | 20 to 30 | 30 above |

| Tolerance | ±0.02 | ±0.025 | ±0.03 | |

| Length Tolerance | Length Size | 5 to 30 | 30 to 100 | 100 above |

| Tolerance | ±0.02 | ±0.03 | ±0.035 | |

| Tolerance Class followed | Tolerance (mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.015 | ±0.02 | ±0.03 | ±0.05 | ±0.10 | ±0.15 | ±0.02 | ±0.025 | ±0.03 | ±0.035 | ±0.02 | ±0.03 | ±0.04 | ±0.05 |

| Type of Milling Machine | Diameter Size (mm) | Length Size (mm) | Productivity (PCS/Month) | |||||

| Vertical Milling Lathe | 3 Axis Milling | 4 Axis Milling | 5 Axis Milling | Min 5 | Max 300 | Min 5 | Max 800 | 100’000/Item |

Yes, we support ODM/OEM, we provide custom-made service for clients or even support clients on designing or improving