In the past few years, woodworking machinery has become one of the most important kinds of mechanical equipment for manufacturing wood products in the world. It is an indispensable part of modern production facilities

Woodworking machinery is used to produce various kinds of wood products such as furniture, toys, marine parts and so on. It can also be used to produce various kinds of wooden items such as doors and windows

The most prominent advantage of woodworking machinery is that it can be used for mass production. With high production capacity, it can meet the needs of customers with different requirements and different products at a higher level than before

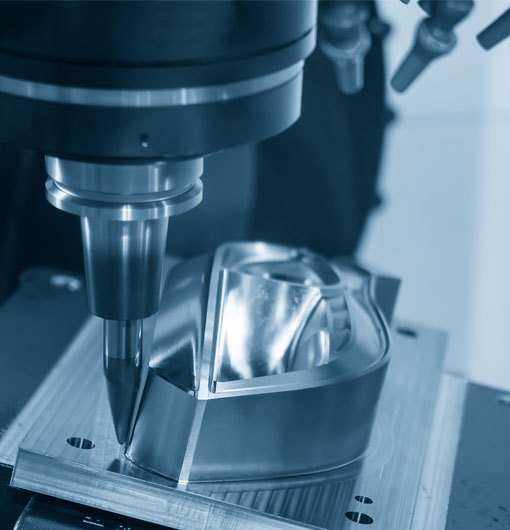

In fact, there are three types of boring machines: semi-automatic boring machine (SBM), CNC boring machine (CNC) and automatic boring machine (ABM). They have different operational speeds and power consumption rates. However, all these machines have similar working principle and function in principle. In addition to this common feature, there are some differences between them that you should know about before you buy one or rent one from us

1﹜Automatic boring machine is more suitable for producing high-quality products with fine details

2﹜CNC boring machine has more complex structure

cnc boring milling machine factories