1. Clean it regularl

The easiest way to keep your router drilling machine working smoothly is to clean it after every use. This includes removing the chuck and using a brush to remove any dust or debris from the machine itself and from under the table. You can also use a damp cloth to wipe down any parts that are exposed while drilling or milling

2. Use quality material

When it comes to buying tools, you can never go wrong with high-quality products. Buy the best quality you can afford, even if that means spending more money upfront. You will be able to avoid future repairs or replacement parts when they break down, saving you time and money in the long run

3. Keep away from wate

Keep your CNC router drilling machine away from water at all times as this can cause damage to its components over time due to rust and corrosion buildup on metal surfaces inside the machine itself and around moving parts such as belts, gears and pulleys etc..

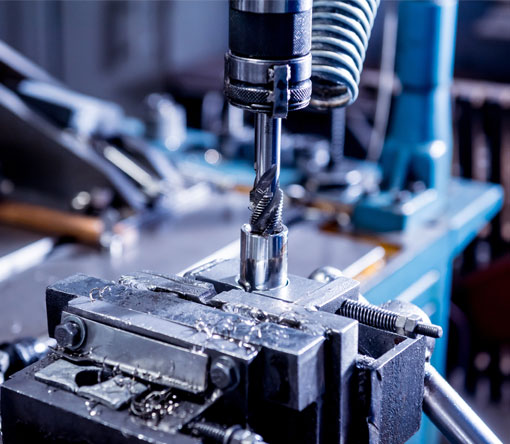

cnc router drilling machine