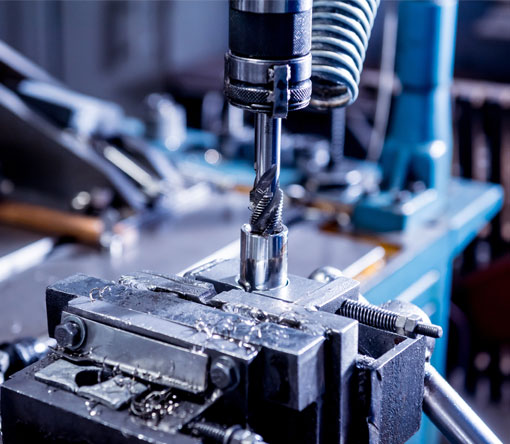

Turning drilling is a process in which a tool is rotated at a high speed to create a hole. The tool can be held stationary or rotated using a chuck, spindle or other holding device

The turning drilling cycle consists of six main steps

1. Turning – The machine rotates the workpiece, usually with a gear system

2. Drilling – The rotation of the workpiece creates a hole in it. This can be either by deep drilling or shallow drilling depending on the type of tool used and the material being machined

3. Cooling – The cooling process helps to prevent thermal shock that may occur when machining out of material at high speeds. Cooling also helps to ensure that chips are removed from working areas, so that they do not clog up machines and cause overheating problems or other damage to machinery components or operators* bodies if they are caught in machinery systems such as chucks or spindles."

cnc turning drilling cycle