Tolerances in CNC Machinin

Have you recently begun machining your own parts? If so, you've likely come across the term "drilling tolerances" While this term may seem simple to some perhaps not everyone understands what it means and how important it is to follow them. In this article I will explain drilling tolerances and why they are needed in your project plannin

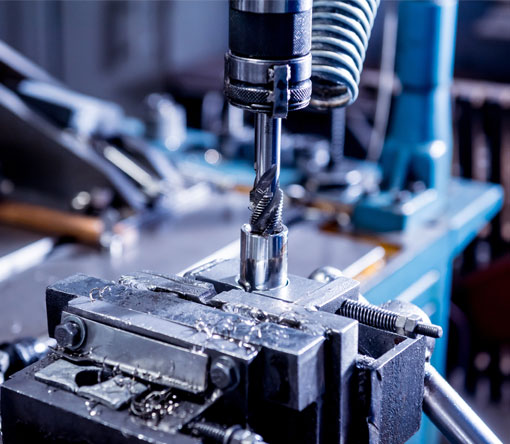

Tolerances are defined as the deviations or variations from a specific dimension. In CNC, drilling is a process that involves cutting a hole in a workpiece with a tool called a drill bit. The size of the hole can be controlled by adjusting the drill bit. However, if the size of the hole is not controlled, it will have an impact on the quality of your part. This is why drilling tolerances are an important aspect of CNC machining projects

The purpose of tolerancing is to ensure that the part being produced accurately meets its design specifications while also meeting manufacturing process requirements and specifications. For example, if you ordered an aluminum extrusion but wanted it cut into thin strips so that they could be used as rivets or bolts; then you would need to specify this when ordering

cnc drilling tolerances